Pig

Pigs are used for cleaning the pipelines from liquids, separating transitional products and fabrications from a pipeline filling pipelines with liquids, cleaning solids and sediments, brushing, and different applications in pipelines.

Cleaning Pig

Cleaning pigs are used for filling and dewatering pipelines in Hydrostatic test, cleaning different kinds of sediments and soot, gas liquids, clay and sandy sediments in pipelines.

These kinds of pigs are designed and manufactured in size of 4-56 inches that can pass through 1.5D-3D bent angles in pipelines.

Cups and discs are made of polyurethane elastomer with high physical and mechanical power and endurance.

According to the customer’s orders our company can supply these kinds of pigs as bellow:

• Capability to install different cups such as conical and heavy duty in size of 4-56 inches .

• Capability to install different discs such as seal discs and guide discs in size of 4-56 inches.

• Capability to install 2,3 or 4 cup or discs or combination of cups and discs.

• Capability to install magnet equipped with flush-system.

• Capability to install pig tracker disc to attach pig tracker into the pig body.

• Capability to install bumper on pig to prevent damages resulted from pig clash with the receiver.

• Capability to install wheel on pig body.

• Capability to install Rotatory brush ,stalk brush and spring brush in size of 4-56 inches that are made of stainless steel and carbon steel.

• Capability to install Plug and Bypass in order to wash brushes

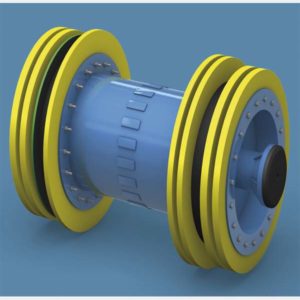

Bi-Direction Pig

Bidirectional pigs are used for filling and dewatering pipelines in water pressure tests (Hydrostatic), cleaning different kinds of sediments and soot, separating two different flows of liquids and reducing humidity in gas flow pipelines. This pre-inspection pig removes ferrous metallic debris, such as welding rods, from a pipeline. It uses strong permanent magnets to collect and hold the debris.

These kinds of pigs cause more cleaning effect because of moving from two sides, so they are cheaper than the other pigs. The advantage of these kinds of pigs is using discs with distances that causes reduction of leakage coefficient, and possibility of reverse motion (reverse motion of pig in process of driving a pig out or removing huge amounts of sediments in Gas lines is useful and sometimes due to fluctuation of pressure is inevitable).These pigs are designed, which could pass through 1.5D-3D angles in pipelines . Discs are made of polyurethane Elastomeric with high physical and mechanical power.

According to the customer’s order our company has below abilities:

• Capability to install different discs such as Seal Dick and Guide Dick in sizes 4-56 inches.

• Capability to install 2, 3 or 4 discs.

• Capability to change diameter, thickness and disc material, spacer.

• Capability to install aluminum or steel gauge plate for checking pipes which have deformed and become out of being circle or have internal damages.

• Capability to install flush-equipped magnet.

• Capability to install pig tracker disc to connect pig tracker into pig body.

• Capability to install bumper on pig to prevent damages resulted from pig crashes into the receiver door.

• Capability to install wheel on pig body.

Batching Pig

Batching pig is used for filling and dewatering pipelines in water pressure tests (Hydrostatic), separating diverse liquids in multi-purpose pipelines and provides a highly reliable barrier between dissimilar products in the pipeline, such as jet fuel and gasoline, protecting pipeline owners and operators from the significant costs associated with product mixing and contamination .

These kinds of pigs are designed and manufactured in size of 4-56 inches. That can pass through more than 1.5D-3D angles.

Cups and discs are made of polyurethane Elastomeric with high physical and mechanical power.

According to the customer’s orders our company has below abilities:

• Capability to install different kinds of cups such as conical and heavy duty in size of 4-56 inches.

• Capability to install different kinds of discs such as Seal disc and Guide disc in size of 4-56 inches.

• Capability to install 2,3 or 4 cups or discs or both cup and disc.

• Capability to change the diameter, thickness and material of cups and discs, spacer.

• Capability to install Aluminum or steel gauge plate for checking pipelines which have become out of circle shape or internal damages in pipelines.

• Capability to install flush-equipped magnet.

• Capability to install pig tracker disc to join pig tracker to the pig body.

• Capability to install bumper on pig to prevent damages resulted from pig crashes into receiver door.

• Capability to install wheel on the pig body.

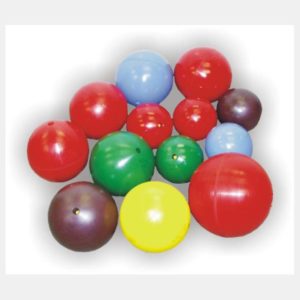

Sphere Pig

Sphere pig is used for filling and dewatering pipelines in water pressure tests (Hydrostatic), cleaning different kinds of sediments and soot, separating diverse liquids in multi-purpose pipelines.

These kinds of pigs are designed and manufactured in sizes 4-56 inches , that can pass through less than 1.5D and acute angle bents. They also have the very high flexibility and commensurability.

According to customer’s orders our company has below abilities:

• Capability to design and manufacture solid sphere pig in size of 4-56 inches.

• Capability to install magnet equipped with flush system.

Solid Cast Pig

Solid cast pigs are used for filling and dewatering pipelines in Hydrostatic tests, and separating diverse liquids.

These kinds of pigs are designed and manufactured in size of 4-56 inches, that can pass through 1,5D-3D or lower angles.

Because of being polyurethane this kind of pigs are highly flexible and can pass more easily through pipelines.

According to customer’s orders our company has bellow abilities:

• Capability to install aluminum or steel gauge plate for checking pipelines which have deformed and become out of circle shape or have internal damages.

• Capability to install Carbon steel, Stainless steel rotary brush in size of 4-56.

• Capability to manufacture one-piece and multi-piece pig.

• Capability to manufacture hollow body for transmitting materials separately.

Foam Pig

Foam pigs are a versatile type of pipeline cleaning device which used for filling and dewatering pipelines in pressure tests (Hydrostatic), and swabbing.

This kind of pigs are designed and manufactured in size of 4-56 inches, that can pass through 1.5D-3D or acute angles in pipelines .

Being completely made of polyurethane and being spongy, they are highly flexible.

According to customer order our company has below abilities:

• Capability to install Aluminum or steel Gauge plate for checking pipelines which have been deformed and become out of being circle or got damaged.

• Capability to install magnet equipped with Flush-system.

• Capability to manufacture in a low/medium/high density shape.

• Capability to manufacture crisscross , Single-spiral, multi-spiral, brushed, magnetic, complete-coated, and corded foam pigs

• Capability to design and manufacture single-nosed and double-nosed foam pig.

Spare Parts Pig

Shegarf Company undertakes all the spare parts of its products for it’s customers. All your need spare parts will be produced and sent you as soon as possible.

Spare parts are:

• Cups (different sorts of cups in size of 4-56 inches made of polyurethane with various hardness).

• Discs (different kinds of discs in size of 4-56 inches made of polyurethane with various hardness).

• Bumper (different kinds of bumpers made of polyurethane with various hardness).

• Circle brush (different kinds of circle brushes sized 4-56 inches made of Carbon steel, Stainless steel).

• Spring brush (different kinds of spring brush sized ۱۶-۵۶ inches made of Carbon steel, Stainless steel).

• Stemmed brush (different Stemmed brush in size of 16-56 inches made of Carbon steel, Stainless steel).

• Magnet (different kinds of magnets in different sizes and changeable).

• Steel body of pig (different kinds of steel body sized 4-56 inches).

• All metal and none metal parts of pig.